Product

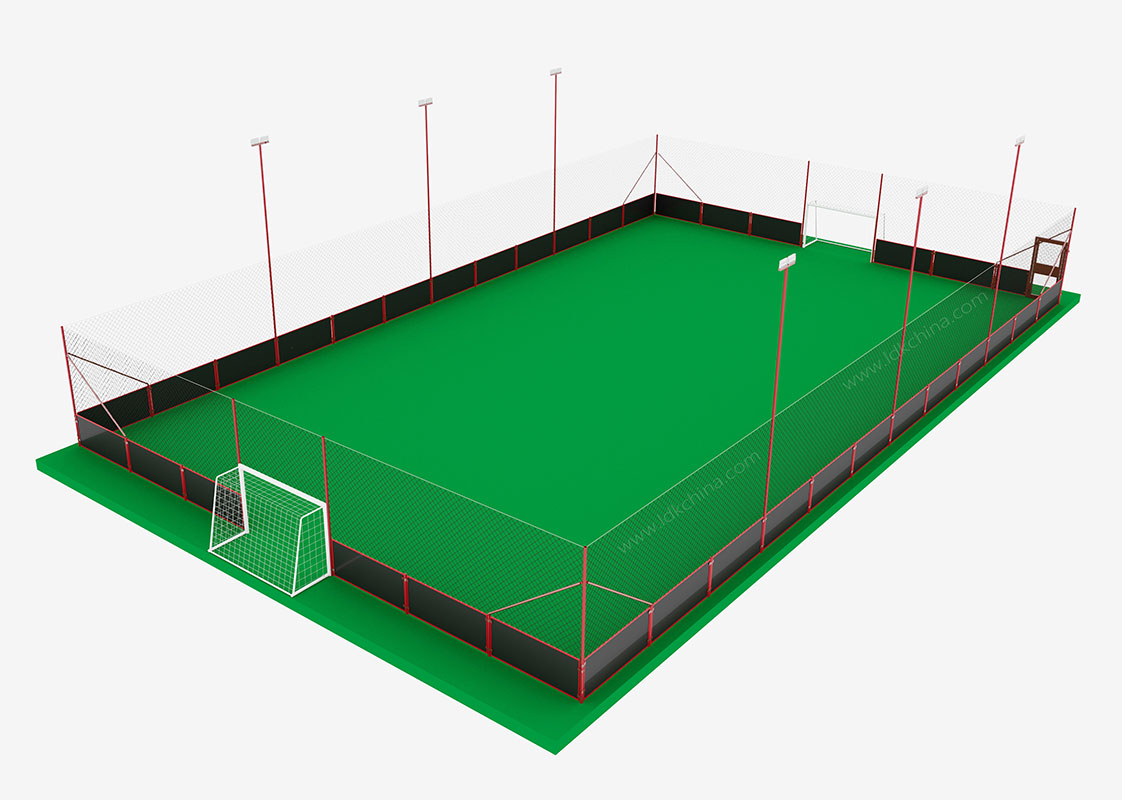

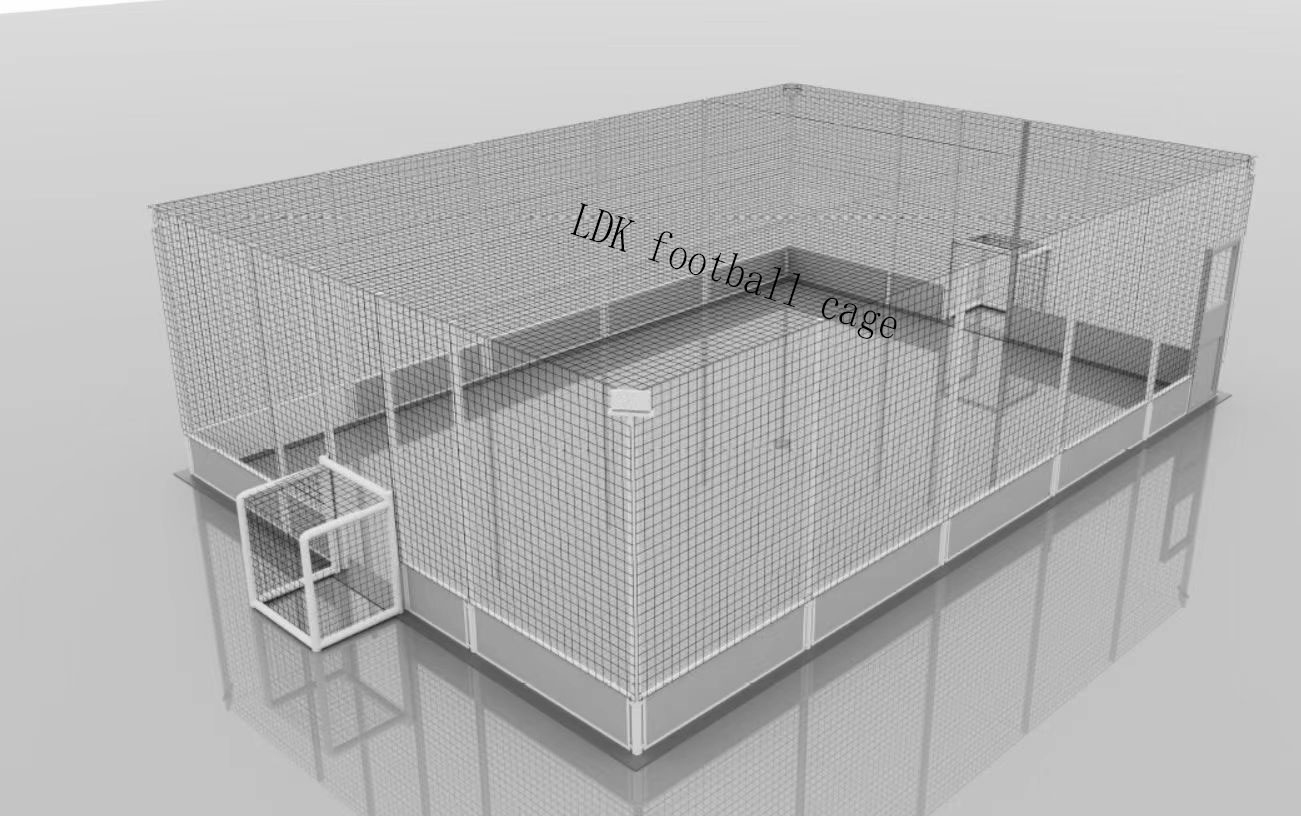

The best cage football field construction plan

Basic Info

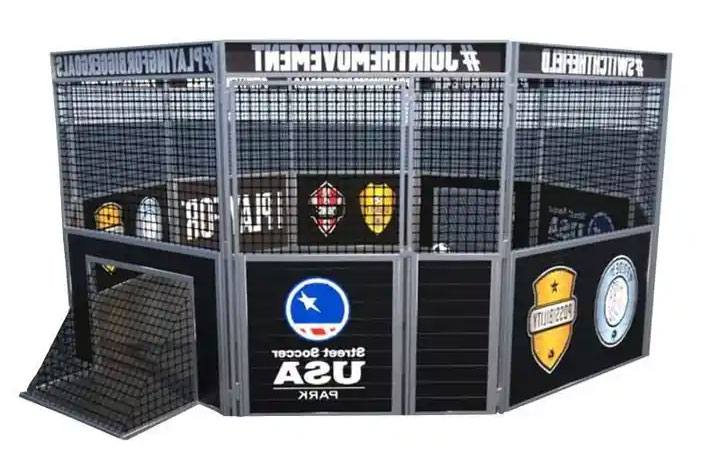

The English abbreviation of Cage Football is P.K.O. So far, P.K.O has complete game rules: it is played in a 6-meter-diameter iron cage, each team has three people, the time limit is three minutes, and only shots from the opponent's half or shots from their own half that touch the opponent's body enter the net. is effective. P.K.O uses rap music as its accompaniment, which is easily accepted by young people who are deeply influenced by American culture. Cage football is becoming increasingly popular in China, and more and more white-collar workers are accepting this "happy football".

Cage football field construction specifications and standards

1. Size requirements:

◎Site size: 25m long, 15m wide.◎Buffer zone: ≥1.5m outside the side line, ≥1.5m outside the end line.

◎Area: The area of the cage football field is not less than 600㎡’

◎Goal size: 3m long, 2m high.

◎Penalty area line: Take a midpoint on the goal line between the two goal posts, take this midpoint as the center of the circle, and draw an arc with a radius of 5m into the field to connect with the goal lines on both sides of the goal posts. This area As a penalty area.

◎Middle circle: Take the center of the court as the center of the circle and draw a circle with a radius of 3m as the middle circle.

◎Line width: The boundary line is always 8cm.

2. Lighting requirements:

◎Light poles should be installed 1.5m away from the side lines and end lines;◎The height of the light pole is above 6m;

◎The illumination of the venue shall not be less than 150lx.

3. Seine requirements:

◎The height of the fence should be ≥6.0m;◎The fence should be set up 1.5m away from the side lines and end lines;

◎The size and spacing of fence posts should be considered in conjunction with the wind power and related factors in the area;

◎The fence gate should be ≥1.0m;

◎It is recommended that the pillars be equipped with safety protection.

Site basic requirements

◎Foundation foundation: Cage football artificial turf field foundation, cement concrete foundation and asphalt foundation are commonly used in the industry. This article introduces in detail the construction and acceptance standards of the above two common artificial turf football field foundations: flatness, slope (drainage design), foundation strength and stability.1. Cement concrete foundation construction standards: Cement concrete foundation construction (cement concrete site foundation must have three major parameters: flatness, slope, strength and stability)

★ Site dimension marking: Use measuring tools to accurately measure the site dimensions, and mark each site size with different bright colors.

★ Flatness: The flatness error of the construction site is controlled within the allowable range, ensuring an error of 3 mm for a 5-meter ruler.

★Drainage: The foundation of the cage football field adopts a turtle-back drainage design. It is appropriate to control the base slope of the site at 3‰-5‰. For specific slope requirements, the slope of the central site is controlled at 3‰-4‰, the slope of the curve is controlled at 8‰, the straight road is controlled at 5‰, and the semicircular area is controlled at 5‰ (the site maintains The surface is flat, smooth and easy for site drainage).

★Compression resistance and stability: Use a medium-sized roller compactor to compact the foundation, and the cushion foundation must be compacted, and the compaction density should be controlled above 95%; when the roller compactor is squeezed, ensure that there are no obvious wheel marks or loose soil , waves and other phenomena to ensure that the basic site has a certain degree of pressure resistance and stability.

★Waterproof layer: A waterproof layer must be built on the cement concrete base layer. The raw material used in the waterproof layer is new PVC thickened waterproof film.

★Maintenance period: The maintenance period of cement concrete foundation is 21 days.

2. Asphalt foundation construction standards: The construction of asphalt site foundation is the same as the cement concrete foundation. It must have three major parameters: flatness, slope, strength and stability.

★Smoothness: The compliance rate of the asphalt site foundation flatness compliance index is above 95%, and the flatness error is controlled within 3 mm of a 3-meter ruler.

★Drainage: The slope is controlled at 1‰-4‰. The specific slope index is as follows: horizontal <1‰, longitudinal <1‰, high jump area <4‰. The slope surface should be kept flat and smooth to ensure normal drainage (the drainage system will be closed half an hour after heavy rain) The accumulated water must be drained out).

★Surface requirements: The asphalt base is preferably made of asphalt materials that do not contain wax or contain very little wax, and the asphalt mixture must be fully compacted. The surface is uniform and solid, smooth with no cracks, no rotten edges, no pitting, and smooth seams. The gravel diameter of the asphalt concrete surface layer is 2-5 mm, and the oil content is 5.8-6.4%. The gravel particle diameter of the joint layer is 6-9 mm, and the oil content is 4.6-5.8%. There is no softness and peeling, no loose soil, and Waves and other phenomena.

Artificial turf requirements

◎Filled type

Lawn height: 50~60mmLawn density: 9500~10500 needles/square meter

Quartz sand requirements: particle size 0.3~1.5mm, silicon content above 90%

Site sand filling capacity: 20-30KG/square meter

Rubber particle requirements: particle size 1mm~3mm

Rubber granule filling capacity: 5~7KG/square meter

◎Filling-free type

Lawn height: 25-30mmLawn density: 16800-21000 needles/square meter

No fillers required

Artificial turf surface acceptance standards and maintenance

1. Acceptance criteria:

(1) Venue appearance:① The artificial grass is uniform in color, and the colors of various road lines and point lines are uniform and bright, with no color difference.

②The width, size and positioning of each functional line and point line are accurate, and the size of the functional area meets the standards.

③ There is no obvious gap between the two turf joints, and the bonding is compact and does not open the glue.

④The surface of the filled sand and rubber particles is clean, the filling is full, and there is no obvious height difference.

(2) Filler thickness: According to the rebound performance of the ball in actual use of this brand of artificial grass, as well as the requirements of relevant international and domestic authoritative agencies, the amount and filling method of artificial grass are determined according to the model and height of the artificial grass. The general filling method for artificial grass is: the bottom layer is filled with 40-60 mesh quartz sand, and the upper layer is filled with 16-24 mesh rubber particles. The two layers are filled separately and cannot be mixed.

(3) Flatness and slope: Flatness requires that the three-meter ruler shall not exceed 3mm, and the drainage slope of the site shall not be less than 0.4%.

(4) Dimension accuracy of the distance between each point line: The color and size of the markings of various functional lines and point lines must comply with the requirements of FIFA rules, and the error shall not exceed 2cm.

(5) Artificial grass field performance testing: Any phenomena such as arching, cracks or degumming, or base fabric breakage are not allowed on the ground. Tested on a standard football field, the ball's rebound is 40%, that is, the ball falls freely from a height of one meter and the rebound height is 40cm.

2. Lawn maintenance instructions:

Artificial grass is designed to be durable. Compared with natural turf, artificial grass fields do not need to "rest". Proper maintenance is designed to improve the practicality and aesthetics of artificial grass. The following points will help you extend the service life of your field longer:(1) Basic points: After the sports ground artificial turf is installed, it takes two weeks to stabilize the grass fibers. We recommend that during this period, try not to hold sporting events, and heavy equipment and unnecessary traffic vehicles should not enter the venue. During this period, the frequency of cleaning should be reduced to a minimum, especially when the temperature is high.

(2) Keep it clean: Cleaning the artificial turf is the only effective way to keep your sports field in optimal sports condition. During the period of frequent use of the site, cleaning and maintenance should be carried out once a month, and garbage on the site should be removed in a timely manner.

(3) Control the use of the venue: If time permits, after a sports event is held, try to allow the venue to be maintained for one week before continuing to use it.

(4) Provide enough garbage bins to prevent garbage from overflowing.

(5) Repair minor damage in a timely manner: Early spring is suitable for maintenance and repair of artificial grass fields. Carefully check whether the seams are loose, check whether the entire turf base fabric is damaged, torn, burned, etc., and replenish filling materials in a timely manner.

(6) Put up "No Smoking" and "Strictly No Food into the Venue" signs in the venue.

More LDK football product recommendations:

Football Cage

Futsal Goals

Metal Football Goal

Aluminum Football Goal

Foldable Football Goal

Portable Football Goal

Mini Football Goal

LDK sports equipment manufacturer's promotion is in progress: Click to contact us now